Nanotechnology Applications

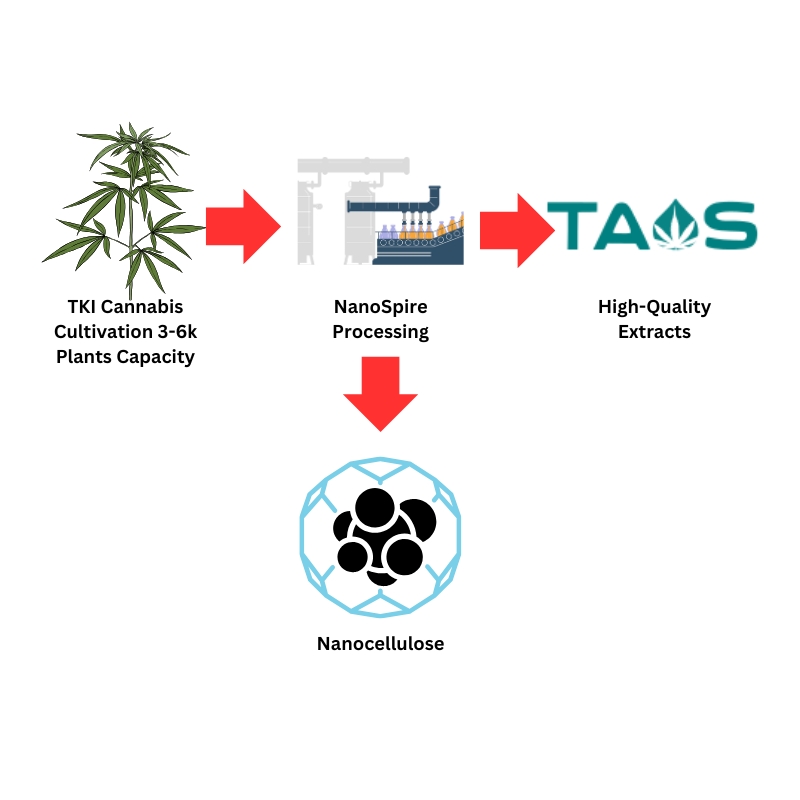

- Deployment of NanoSpire technology to:

- Extract cannabinoids efficiently, preserving therapeutic compounds for premium products.

- Convert cellulose waste into nanomaterials for industrial applications, contributing to cleaner, sustainable practices.

- Positioned to lead in the development of high-value therapeutic and industrial derivatives, promoting sustainability in both cannabis and broader industrial markets.

Comparing Nanospire to Traditional Extraction

A direct comparison between NanoSpire’s technology and traditional CO₂ extraction highlights the advantages of nanotechnology:

•Yield: Nanospire provides a 20-30% higher yield compared to CO₂ extraction.

•Processing Time: Nanospire reduces processing times by 70%, increasing overall throughput. In other words, Supercritical CO2 extraction takes more than 2 times longer than our system.

•Energy Use: Nanospire requires less than <10% the energy it takes CO2 method. Meaning, Supercritical CO2 extraction requires over 10 times the energy.

•Product Quality: Nanospire ensures that the full spectrum of cannabinoids and terpenes is preserved, resulting in more potent and flavorful end products.